Airtightness

It has gradually become more and more difficult to meet the EPB requirements without paying attention to airtightness. That's entirely logical, as uncontrolled ventilation losses are the reason for large amounts of heat loss, draughts, poor acoustics and moisture problems. Good airtightness and a high-quality building shell go hand in hand.

Furthermore, a good V-50 value (m³/h per square metre of the building shell) – the result of an airtightness test, the blower door test – remains one of the most economical ways to lower the E value and, since 2018, the S value.

Tip

Do not wait to carry out an airtightness test until all the work has been completed. It's better to carry out an initial guidance test when the building is wind-tight. At this point, any large leaks can still be easily rectified. If you wait until the end, that always requires rework and the costs can mount up quickly.

Window-to-wall joints are crucial and can easily amount to 100 m in an average house, while poor execution accounts for an estimated 15% of the total air loss in an average detached house. SWS, the professional window-to-wall system, can therefore make an important contribution to good airtightness.

The SWS model

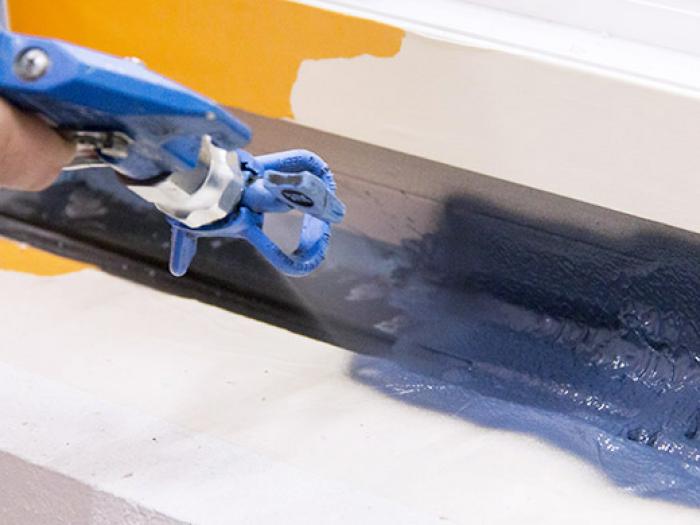

The optimal sealing of window joints consists of good airtightness on the inside, thermal and acoustic insulation in the middle, and excellent protection against the elements on the outside. Soudal has developed a range of three products for the provision of a long-lasting weather tight seal between windows and doors. These products when used in a system have improved performance in terms of thermal and acoustic properties, and are fully airtight.

A typical system set-up is Soudaseal 215 LM providing a flexible sealant on the exterior of the building, with Soudafoam Window & Door SWS providing the thermal and acoustic insulation element and Acryrub SWS as the flexible paintable sealant on the interior of the joint.